Projects

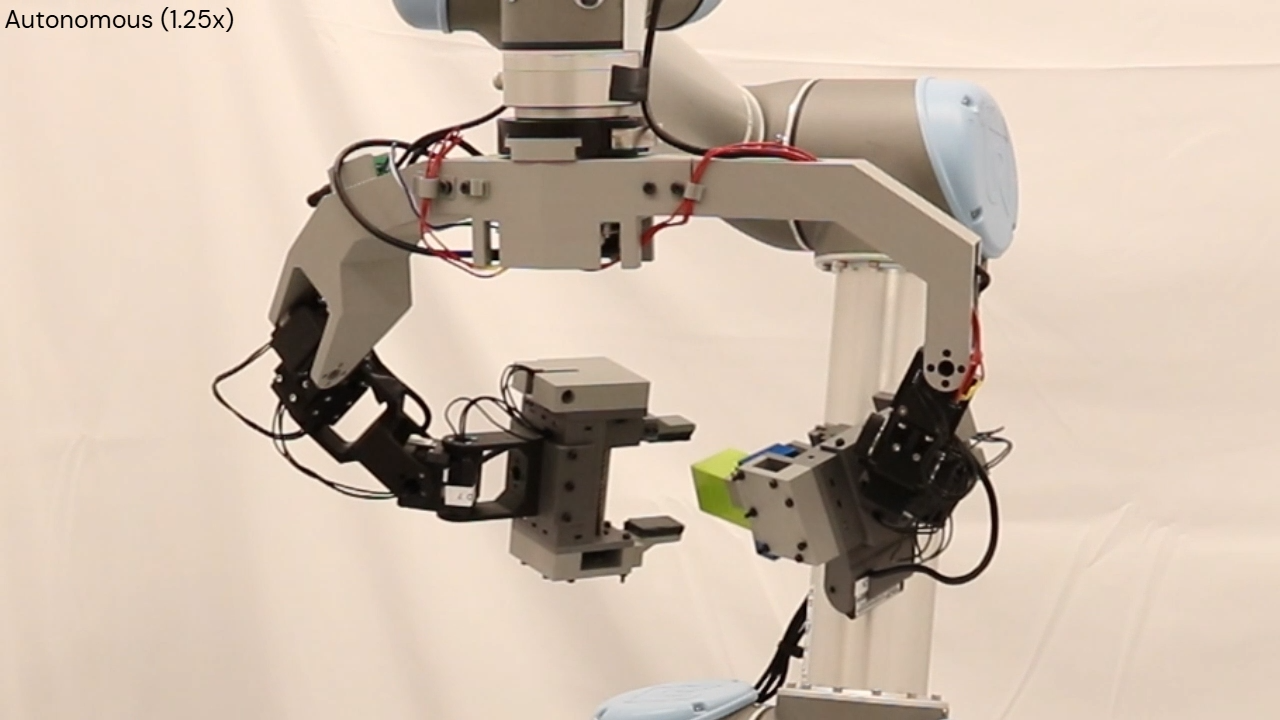

MiniBEE: Mini Bi-Manual End Effector

ROAM Lab, Columbia University — Jan 2025 – Present

• Project Website

• Developing a miniature bi-fingered end effector to improve robot dexterity under Prof. Matei Ciocarlie and the ROAM Lab.

• Conducting kinematic analysis and design optimization in ROS2 to maximize workspace utilization and finger performance.

• Utilizing the MiniBEE to train behavioral cloning diffusion policies for dexterous manipulation tasks.

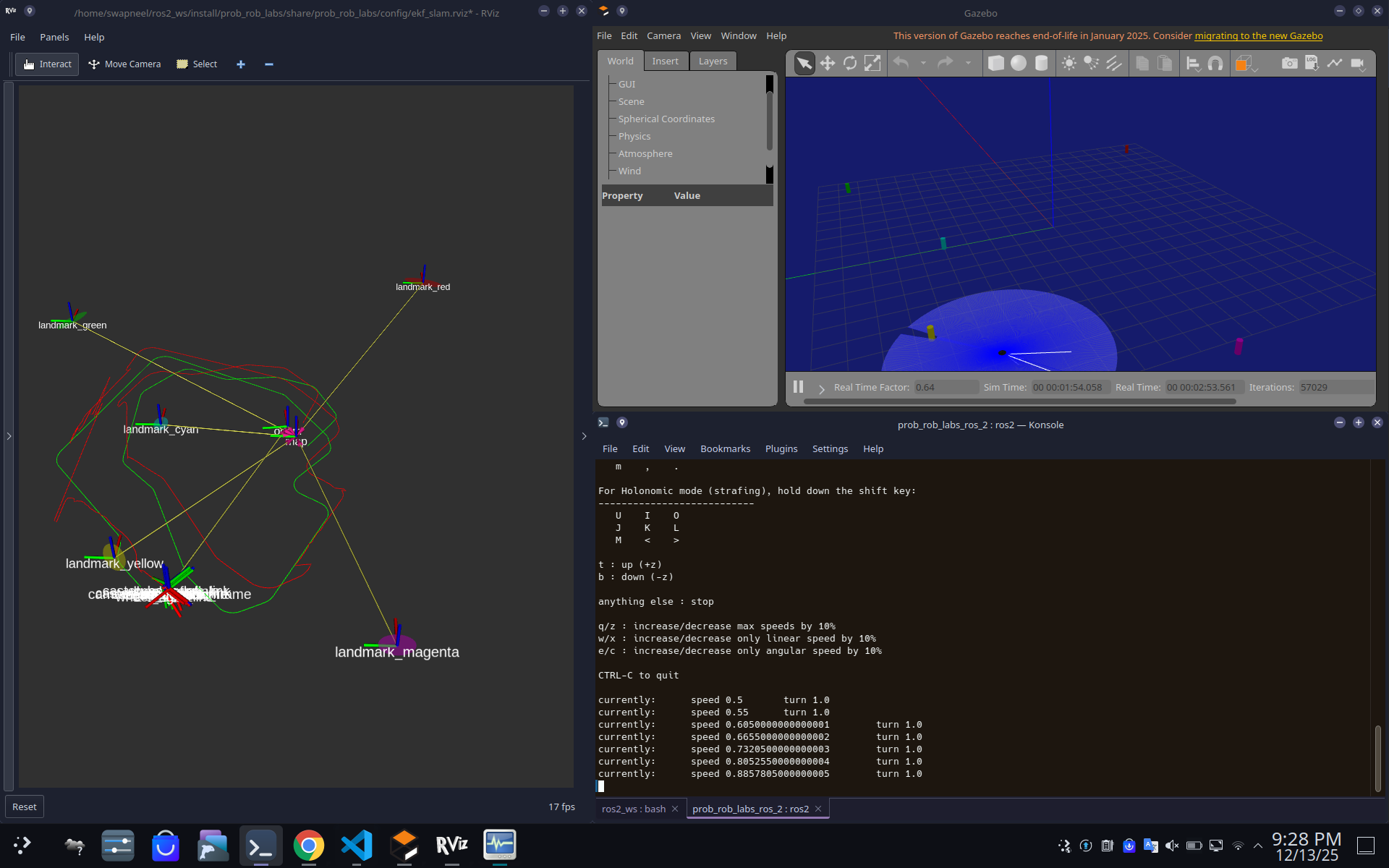

Extended Kalman Filter Slam

Probabilistic Robotics Course, Columbia University

• GitHub Repository

• Developed an EKF SLAM implementation in ROS2 for Probabilistic Robotics Course Project

• Utilised a TurtleBot2 simulation on Gazebo with Rviz2 for visualization.

• Based on algorithms from Thrun's "Probabilistic Robotics" textbook.

• Further improvements include graph-based SLAM techniques, and more sophisticated covariance models.

MPC–ISM Control for Robot Manipulators

Collaborative Project with Onur Calisir — Columbia University, 2025

• GitHub Repository

• Implemented a hierarchical three-layer controller combining Model Predictive Control (MPC) and Integral Sliding Mode (ISM) to achieve robust tracking on nonlinear robotic manipulators.

• Designed inverse dynamics linearization to decouple nonlinear MIMO systems, followed by ISM uncertainty rejection and MPC for optimal trajectory tracking.

• Simulated multi-rate control with fast ISM (1 ms) and slower MPC (20 ms) sampling for a 3-DOF manipulator under uncertainty injection.

• Observed that while MPC handled nominal tracking efficiently, ISM improved robustness against high-magnitude uncertainty by adapting control inputs dynamically.

• Based on the IEEE/ASME paper “MPC for Robot Manipulators with Integral Sliding Modes Generation” by Incremona et al. (2017).

Bipedal Walking Robot

Robotics Studio Project, Columbia University

- Designed, fabricated, assembled, and programmed a bipedal walking robot from scratch with a teammate.

- Performed kinematic analysis of bipedal gait using CAD keyframing and function smoothing.

- Achieved a final walking speed of 10.4 cm/s.

Final Year Project

Developed camera-feed integration for an HMI on a construction-site stair-climbing robot. Performed a literature review of image stitching for 360° views with fisheye cameras and sourced appropriate sensors. Implemented stitching and prepared frames for directional feeds.

Download Project PresentationRobotic Waste Sorting at Robert Bosch

Programmed the IRB120 robot for automated plastic waste sorting on a conveyor using a hybrid AI system (Terahertz sensor + computer vision). Supported classification model development and integrated cameras and mechatronic devices in ROS. Built a live RViz digital twin with metrics on plastic types and picking rate.

Robotic Dishwasher

Engineered a 6-DOF robotic arm and supporting mechatronics to automate dishwashing. Designed trays for dirty/clean utensils and a rinsing/scrubbing station to clean 5+ utensil types. Led controls using ROS, MoveIt!, and Dynamixel Workbench for motion planning and actuation.

Mechatronics System Design Course Project

Designed and prototyped the winning robot for a course competition. Programmed motion and search strategy to locate tennis balls and return them to a drop-off point; integrated sensors with the VEX microcontroller for boundary, pickup, and drop-off status.

Cyborg Beetle — Part-Time Research Assistant

Part-time research with Prof. Hirotaka Sato's team (Apr 2020 – Feb 2021). Designed experiments to evaluate swarm exploration efficiency (sizes 10–100) across algorithms (E. coli-like motion, fixed/variable step length, etc.) using ARGoS 3, and logged performance for comparative analysis.